Surface Treatment

These processes aim to optimize the properties of steel surfaces, for example in terms of corrosion resistance, durability, or aesthetics. In recent years, we have built a comprehensive network of suppliers offering a wide range of surface treatments. Additionally, we carry out various surface processing methods in-house, such as deburring and vibratory finishing (trowalizing). We also offer several options for marking your components.

For advanced finishing processes, we rely on the expertise of our trusted partners. These include galvanizing, hot-dip galvanizing, powder coating, thermochemical surface treatment, painting, carburizing, and Geomet coating. This ensures that your components are optimally protected against external influences and meet the highest quality standards.

Contact us for your individual requirements – we’re happy to advise you!

Technical Data:

Loewer SwingGrinder

- Table size: 800 mm x 1400 mm

Technical Data:

Roll Wash

Contents: Grinding stones with various grit sizes (dry process, no water)

Technical Data:

HGTECH LSF30

- Table size: 360 x 360 mm

- Engraving area: 140 x 140 mm

Technical Data:

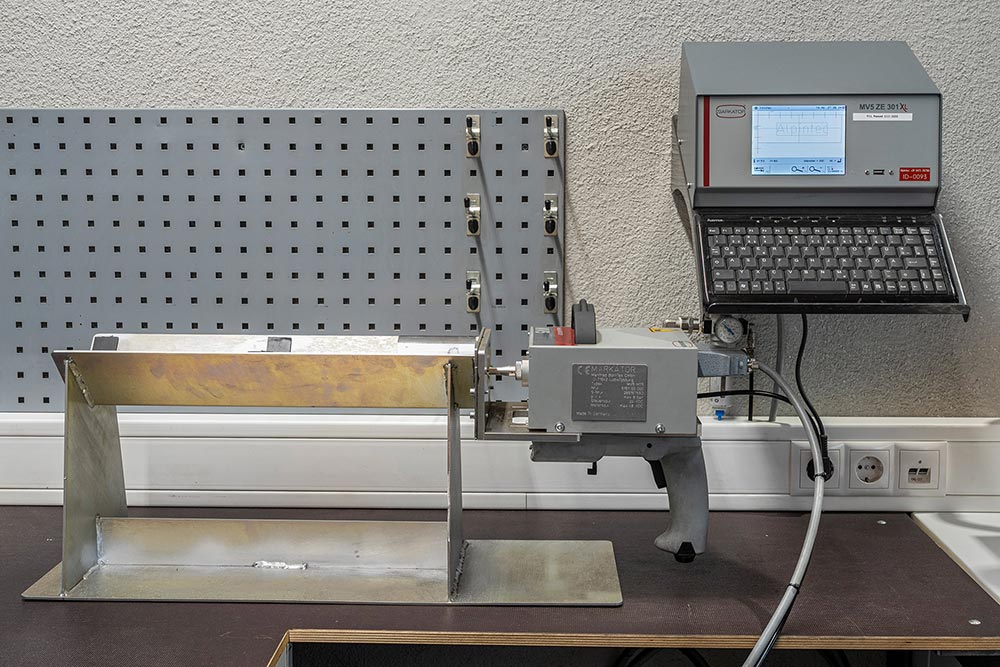

Markator MV5 ZE 301 XL & MV5 M75

- Engraving area: 50 x 45mm