Alpintec Mechanical Engineering

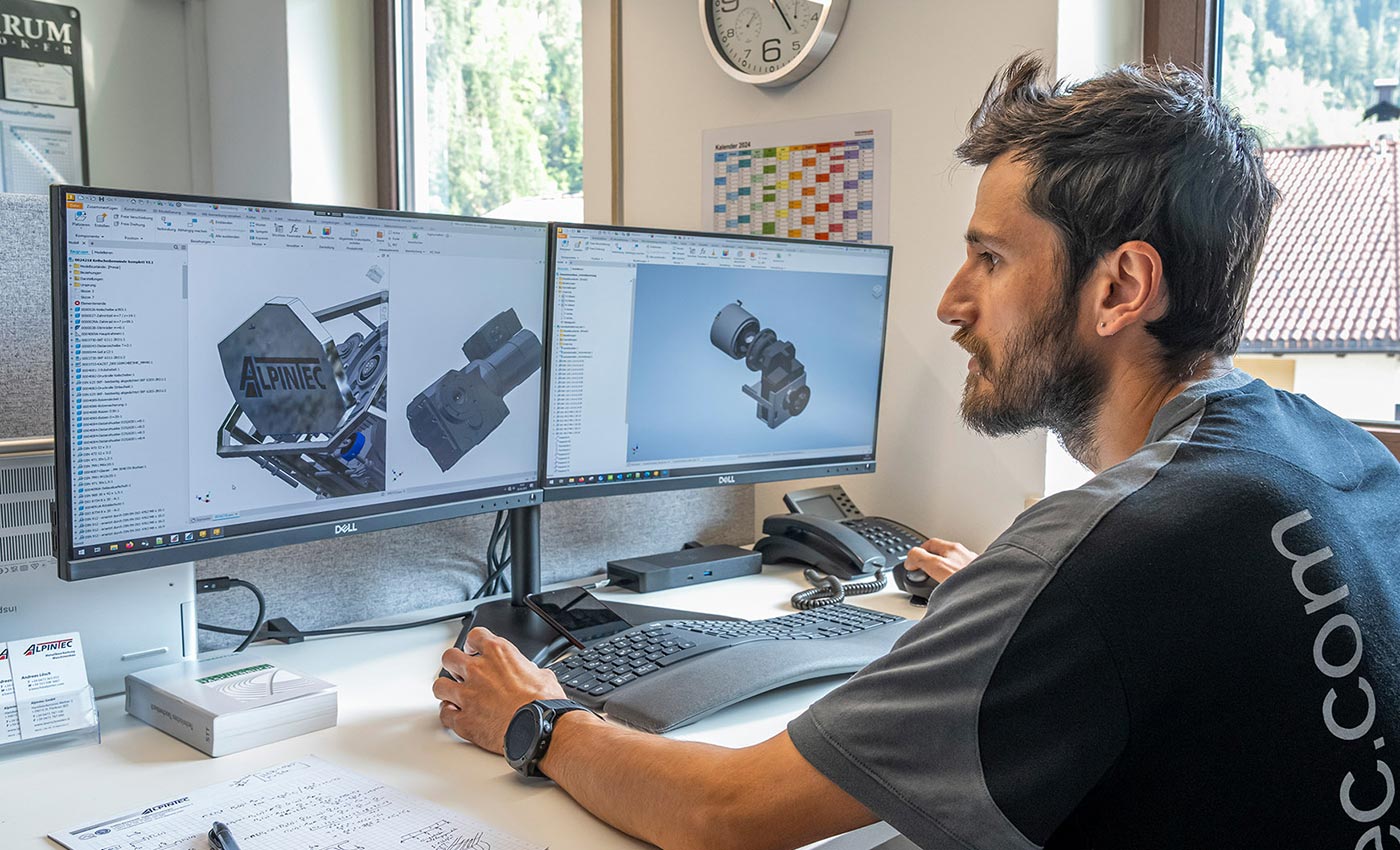

Precision and Innovation in Mechanical Engineering

We are your reliable partner when it comes to metalworking. Our range of services includes everything from sheet metal cutting and bending to turning, milling, welding, and the assembly of complete components.

Since the 1980s, we have been developing and manufacturing special-purpose machines in our own workshop for internal use, gaining a strong reputation in the cable car industry far beyond national borders. In 2017, we made the decision to offer this expertise to external customers as well. Since then, we have continuously expanded and modernized our machinery.

We work with precision and accuracy

Today, we process a wide range of high-quality materials:

• Steel: S275, S355, S700, tempered steels (39NiCrMo3, 42CrMo4)

• Stainless steel: 1.4305 (AISI 303), 1.4301 (AISI 304), and 1.4401 (AISI 316L)

• Special steels: S355J2WP (Corten®), Hardox®450

• Other metals: Brass, Bronze, Aluminum

• Plastics: POM, PTFE

Our customers benefit from our expertise, our modern machinery, and our uncompromising commitment to quality. Whether for one-off productions or medium-sized series, we deliver tailored solutions for a wide range of industries and requirements. Optimized processes and short production times ensure reliable and on-time delivery.

Our Services

Laser cutting

Bending

Milling

Turning

Welding

Surface treatment

mechanical engineering

Always in Sight

Traceability of mechanical components is a top priority for us. Safety-relevant parts demand the highest standards, which we meet through our customer portal: for complete traceability, our customers can view online which materials were used in the production of their components and download the corresponding certificates if needed. They also have access to our current stock levels and are always kept up to date.